Quarried aggregates are an important part of the UK economy. They account for 85% of the non-energy minerals extracted in the UK. The construction industry heavily relies on aggregates to help improve the UK’s infrastructure.

in 2017, over 176 million tonnes of quarried aggregates were produced across Great Britain, making up 70% of the total aggregate supply. With this in mind, we think it’s important to highlight how this vastly used material is produced.

Read about the recycled aggregates production process.

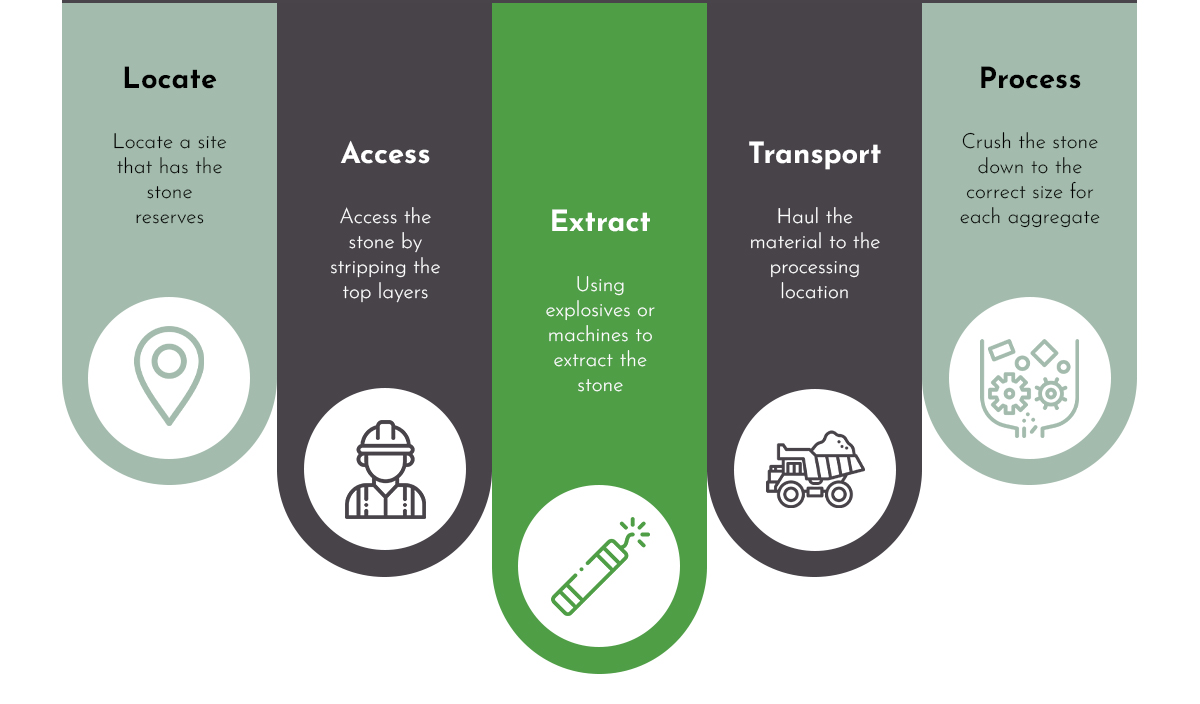

1. Locating the Material

Firstly, you need to locate the material. In the UK most of the sites which have access to raw materials have already been accessed. These sites are also known as quarries, pits or mines.

Once you’ve located a quarry, you’ll need to gain a relevant permit to allow you to conduct quarrying activities.

A quarry plan will need to be approved by a governing body before you can start producing aggregates.

2. Raw Material Access

You need to gain access to the raw material. This may require removing topsoil or a layer of material known as overburden. To strip the overburden, a variety of heavy equipment will be used, this includes excavators, draglines, bulldozers, graders or other earth moving equipment.

3. Raw Material Extraction

Once the raw material has been accessed it then needs to be extracted. There are several methods used to extract stone, but the most commonly used is blasting. Holes will be drilled into the quarry face where explosives will be inserted and detonated. The blasted material is now loose and accessible for transportation and processing

In some cases the raw material can be dug straight from reserves using excavators and peckers. The raw material maybe also be broken down further if the size of the stone is too large.

4. Raw Material Transportation

After extraction, the material will need to be transported to the processing equipment. This is achieved by loading dump trucks and hauling the material to the processing location.

To keep production costs low the processing equipment can be situated close to the material extraction site, helping to save on fuel. If wagons can access the extraction site, they can be loaded directly from there.

5. Aggregate Processing

Once the raw material reaches the processing location it can start to be processed into an aggregate. There are several machines that are used to produce aggregates, these being:

In some cases, further processing may be needed to produce different products, such as lime, that is heated in kilns.

A variety of different aggregates can be produced such a 6F5, MOT Type 1 or 40mm Clean

Sources:

Mineral Products Association and Crown Estate, Great Britain: Summary of aggregates supply, 2017.